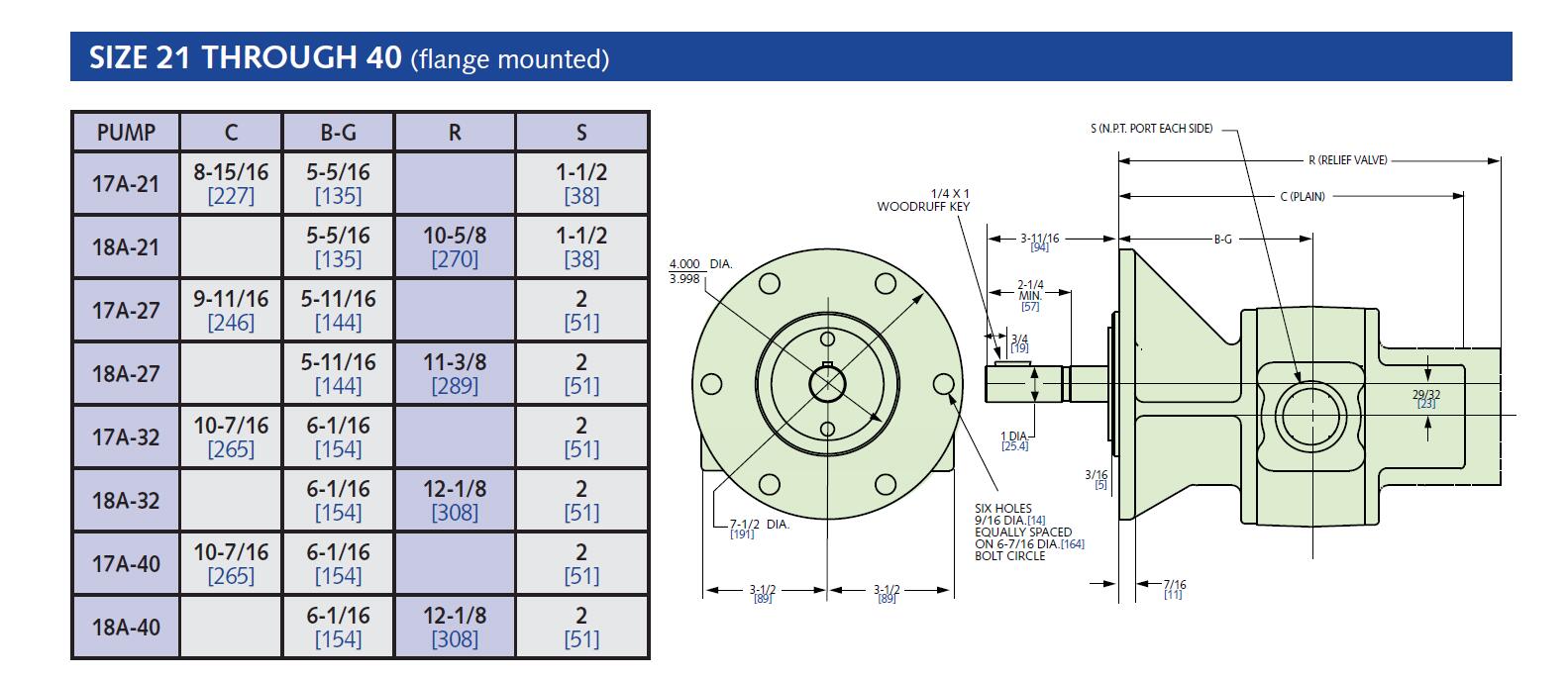

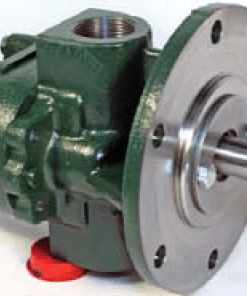

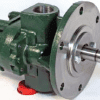

Roper Gear Pump 18AP27

48.8 gpm, 150 psi, 2 in NPT Ports, Flange Mounted with Relief Valve, Packed Box

$1,899.00 Including Tax is $2,360.46

Available on backorder

Description

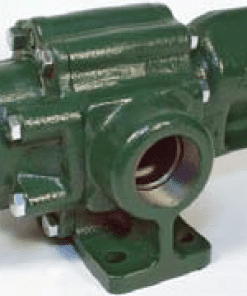

A Series General Purpose Pumps

General Purpose Pumps for Pressure Lubrication, Hydraulic Service, Fuel Supply and General Transfer

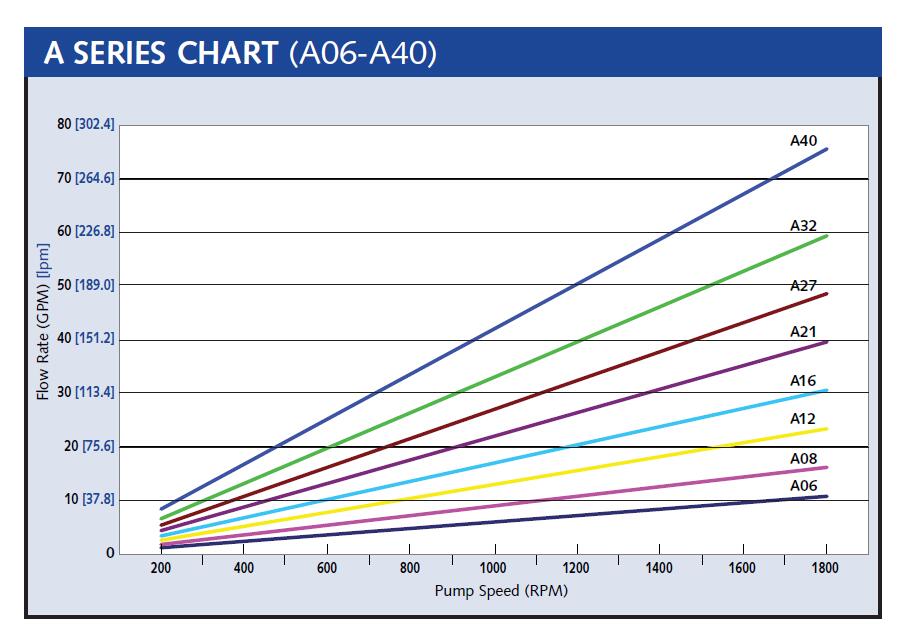

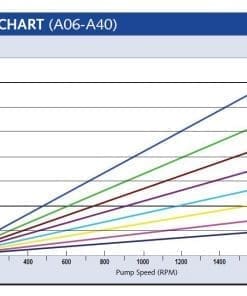

Up to 59 GPM ● Up to 300 PSI

Roper A Series pumps are adaptable to a wide range of applications pumping clean fluids, such as pressure lubrication, hydraulic service, fuel supply or general liquid transfer.

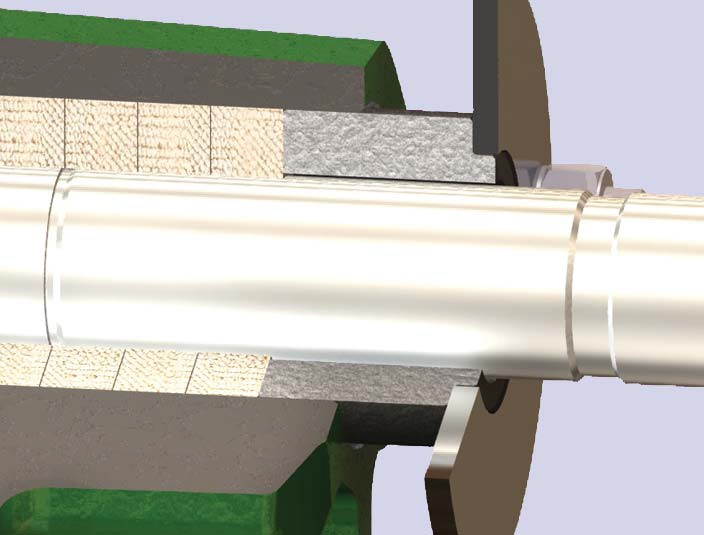

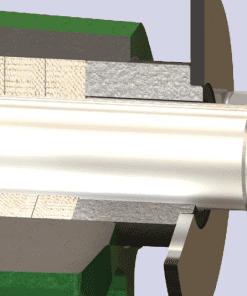

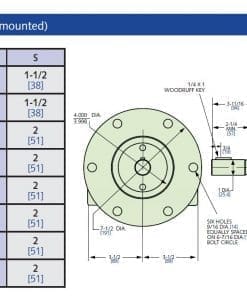

These pumps are designed to operate at standard motor speeds, with provisions for flange or foot mounting. The internal bearings are lubricated by the fluid being pumped. With only two moving parts, the pumps run quietly.

They are manufactured and assembled with close tolerances, and regularly tested to insure dependable performance. Factory assembled for clockwise rotation (facing the pump drive shaft end), most may be reassembled for operation with equal effi ciency in a counter-clockwise rotation.

MATERIALS OF CONSTRUCTION

Standard Fitted

Housing ……………………………………. Cast Iron

Gears ……………………………………….. Ductile Iron*

Hardened Steel**

Bearings……………………………………. Bronze

Idler Shafts ……………………………….. Ductile Iron*

Steel**

Drive Shafts ………………………………. Hardened Steel

Optional Materials

Housing ……………………………………. Ductile Iron***

Bearings……………………………………. Iron, Carbon

*06 and larger sizes. **03 and smaller sizes.

***In 005, 01 and 02 sizes

FEATURES

■ Designed to operate at standard motor speeds

■ Bi-directional rotation

Quiet-Running Helical Gears

Accurate machining insures:

■ proper meshing

■ reduced friction and vibration

■ quiet, efficient operation

■ long life

Long-Lasting Bearing Surfaces

■ Bearings are special wear-resistant, high-lead bronze. (Iron and carbon bearings are available.)

■ Four heavy duty sleeve bearings give positive support to pumping gears and insure long, efficient service.

Precise, Rugged, Maintenance-Friendly Design

■ All castings are cast iron.

■ Precise manufacturing tolerances provide minimum clearances for maximum pumping efficiency.

■ Large, hardened steel dowel pins insure positive alignment between the faceplate, case, and backplate.

Additional information

| Weight | 55 lbs |

|---|---|

| Dimensions | 22 × 12 × 12 in |

| PORT SIZE(in) | 2 |

| MAX FLOW(gpm) | 48.8 |

| MAX SPEED(RPM) | 1800 |

| MAX PRESSURE(psi) | 150 |

| MAX TEMPERATURE(℉) | 250 |

| SEAL OPTION | Packed Box |

| PUMP MODEL | |

| COUNTRY OF ORIGIN | USA |